Note: This guide is based on the IPC 7721 4.2.1 standard. Purchase the full standard from the IPC organization. The graphics and text have been created to provide easy-to-use instructions. Any content that diverges or supplements the IPC standard with be noted on the graphics, and text will be blue.

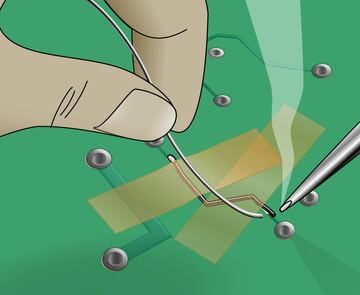

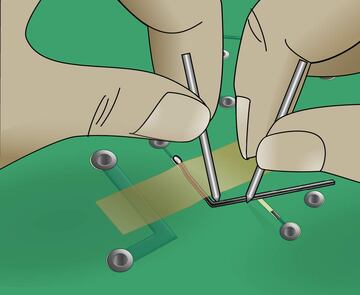

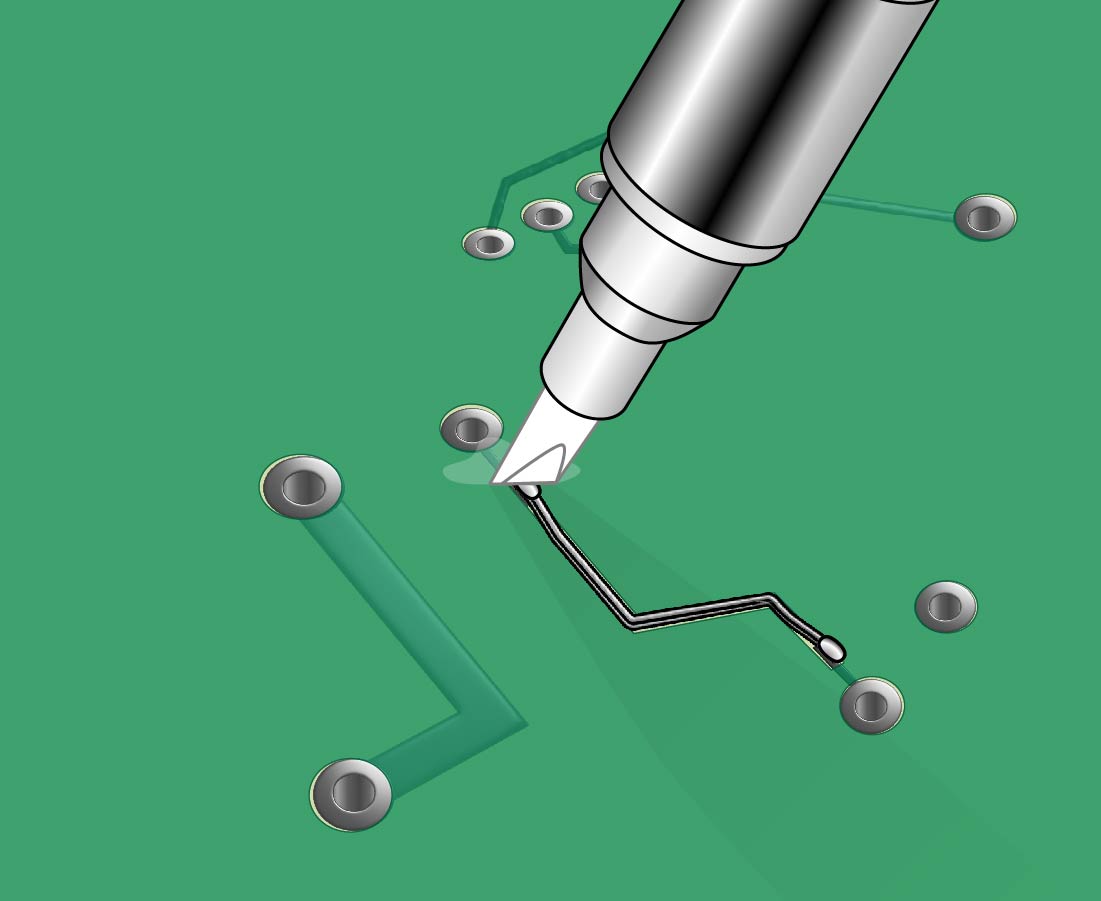

STEP 1: Scrape away resist from repair areas.

|

Scrape away resist.

Clean off resist particulates. |

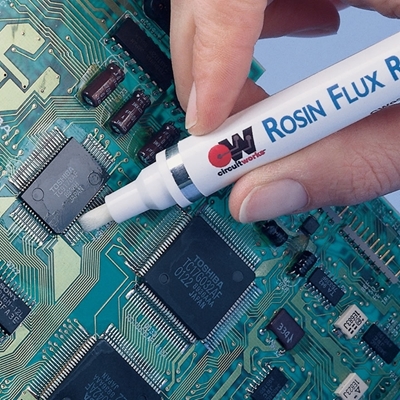

The damaged trace should be cut away and removed using a cutting tool, being careful not to damage any surrounding traces, components and contacts. Whenever possible, this repair should be made at least three millimeters away from contacts that will later be soldered in order to minimize the chance of reflowing the repair. Before pulling off the damaged trace, double-check that your cut is complete. Otherwise you risk lifting up the remaining trace and/or contact. Before you can add a jumper, the conductive surfaces must be exposed at the point of the break. You can use the cutting tool to carefully scrape away at least 3mm length of the overcoat material. A rotary tool grinding bit, held in your hand, is a good tool to gently scrape away resist in a controlled way. Make sure to scrape lightly to avoid damaging the conductive material of the trace underneath. Use an alcohol cleaning wipe, solvent cleaning pen, or some other method to remove overcoat particulates and other residues from the repair area. Apply flux to the existing traces, and use a soldering iron and solder wire to tin each end of the trace. Desoldering braid may be used to remove any excess solder. Clean the area again. |

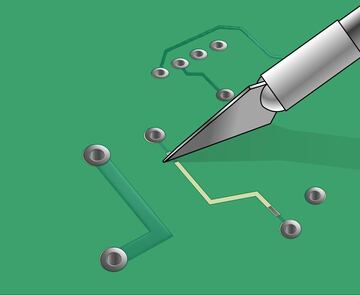

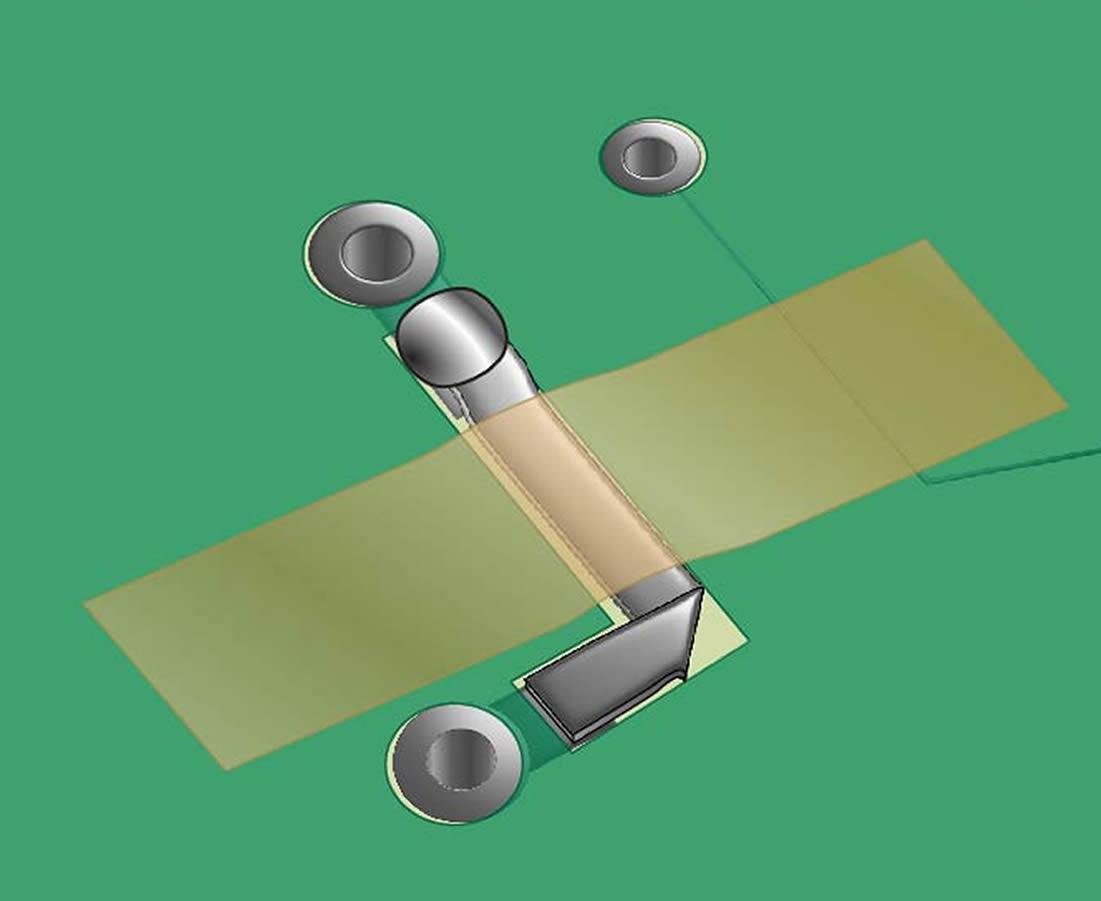

STEP 2: Solder one end of the foil jumper to contact.

|

Solder one end of jumper. |

Choose a copper replacement circuit trace that is the same width and thickness as the damaged trace. Most traces have a thickness of one ounce per square foot (1.37 mils). The replacement trace may be cut from a copper sheet. Cut this trace to the approximate length needed to connect the existing conductors on the board. Scuff both ends of the new copper trace to remove any protective coating on the copper. Lightly tin the surface of both ends of the new copper trace using a soldering iron and solder. Overlap one end of the new trace over the existing trace by at least twice the width of the trace. Hold the new trace in place using polyamide tape placed out of the way of the overlapped connection. Align both ends at the same time If the area of trace being replaced is straight. Otherwise, align only one end of the trace at this time. Apply flux to the overlapped traces and solder them together. |

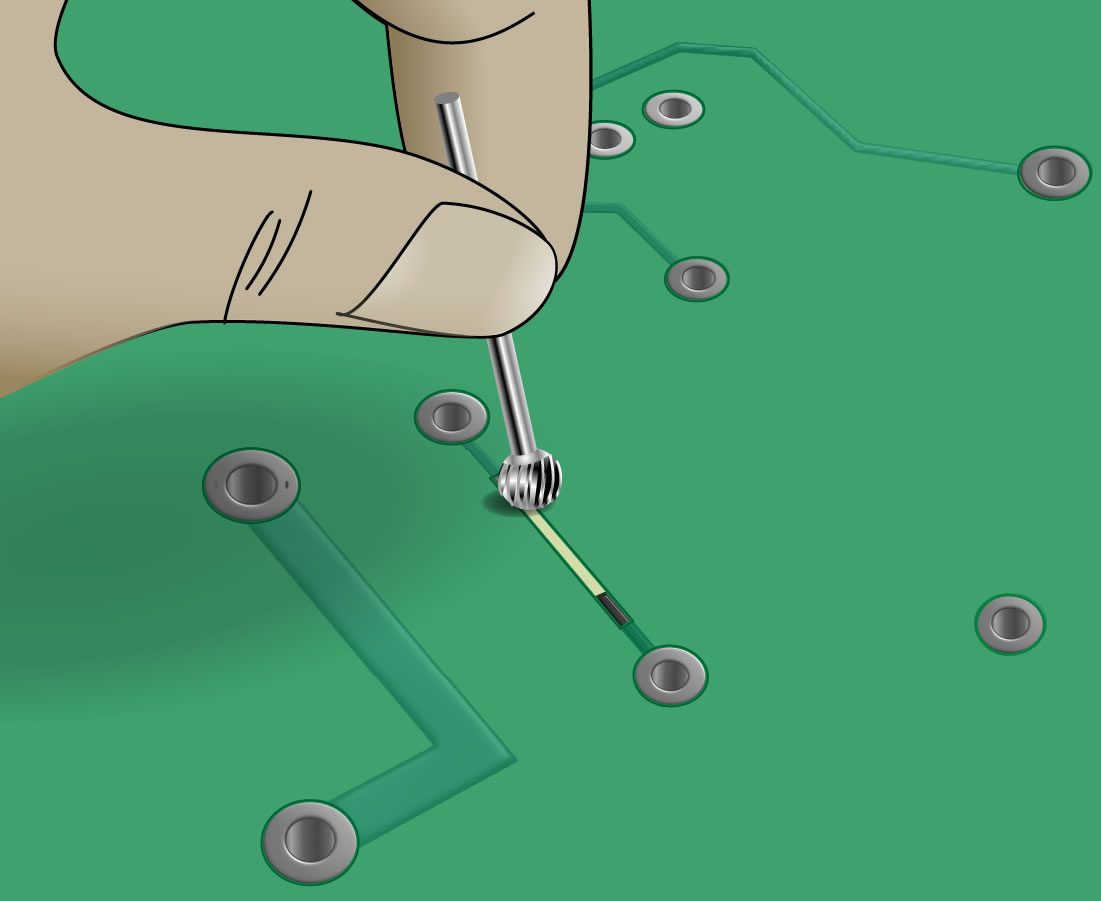

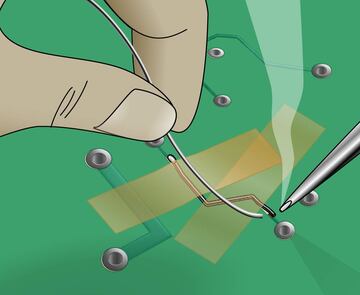

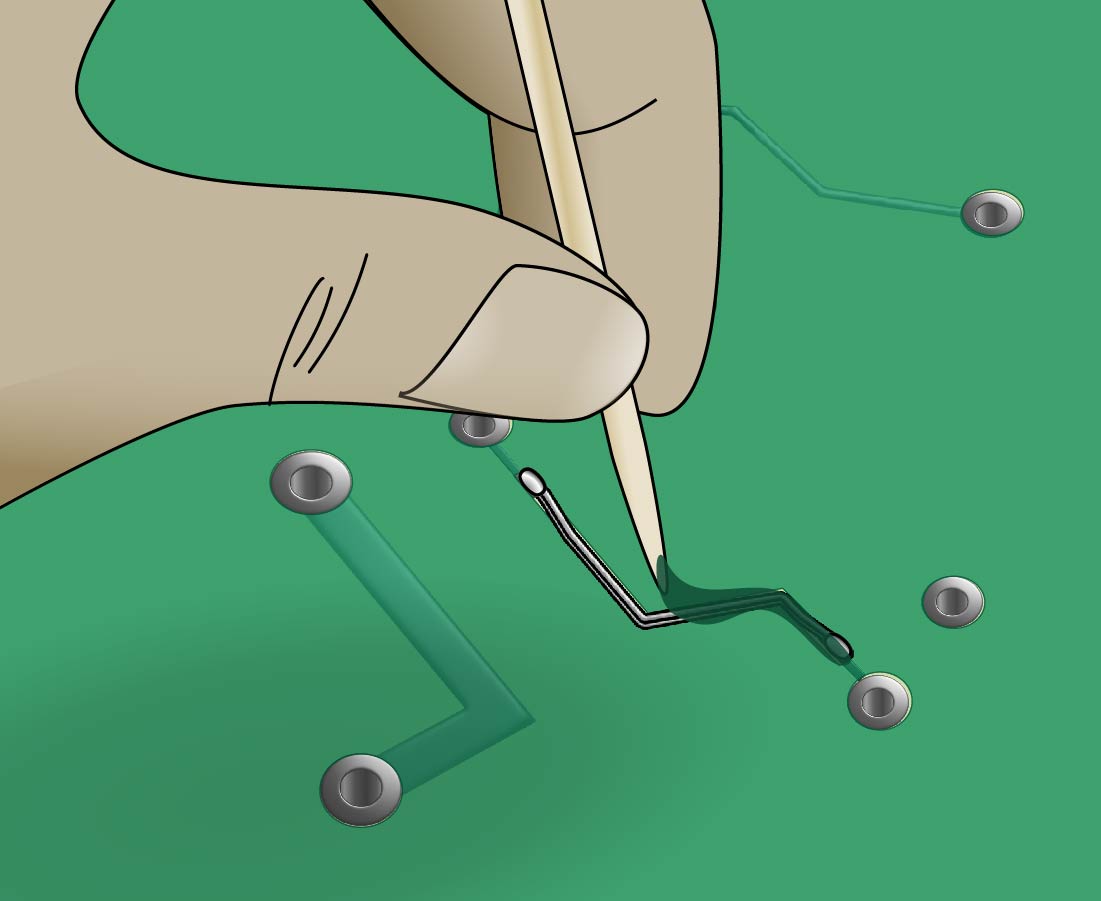

STEP 3: Bend foil jumper to the desired configuration.

|

Bend foil jumper.

Wider jumpers may need to be folded. |

Bend the foil jumper to create a path to the other conductive surface. The shape may be formed using wooden sticks, and additional polyamide tape should be used as needed to hold the foil in place. Wide foil may be folder over to create an angle if needed. Overlap the foil jumper over the existing conductive surface by a minimum of twice the width of the jumper. |

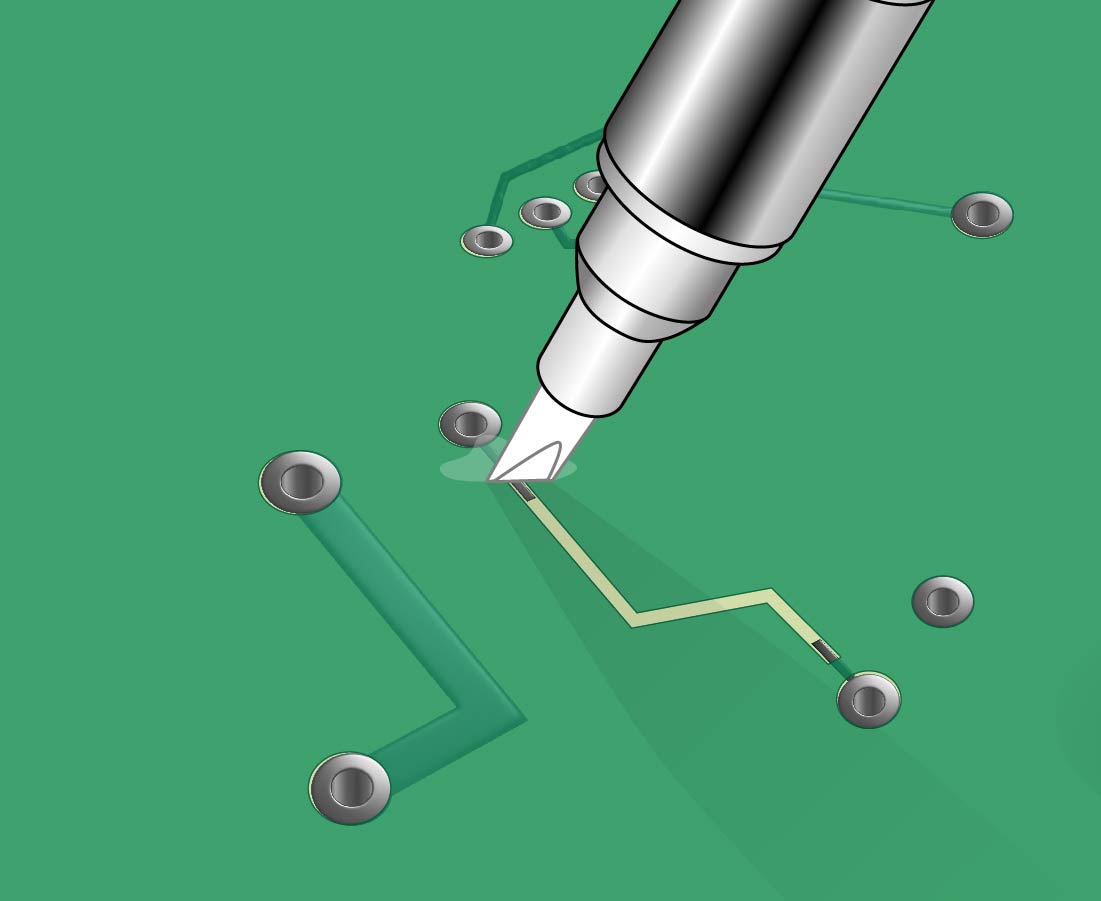

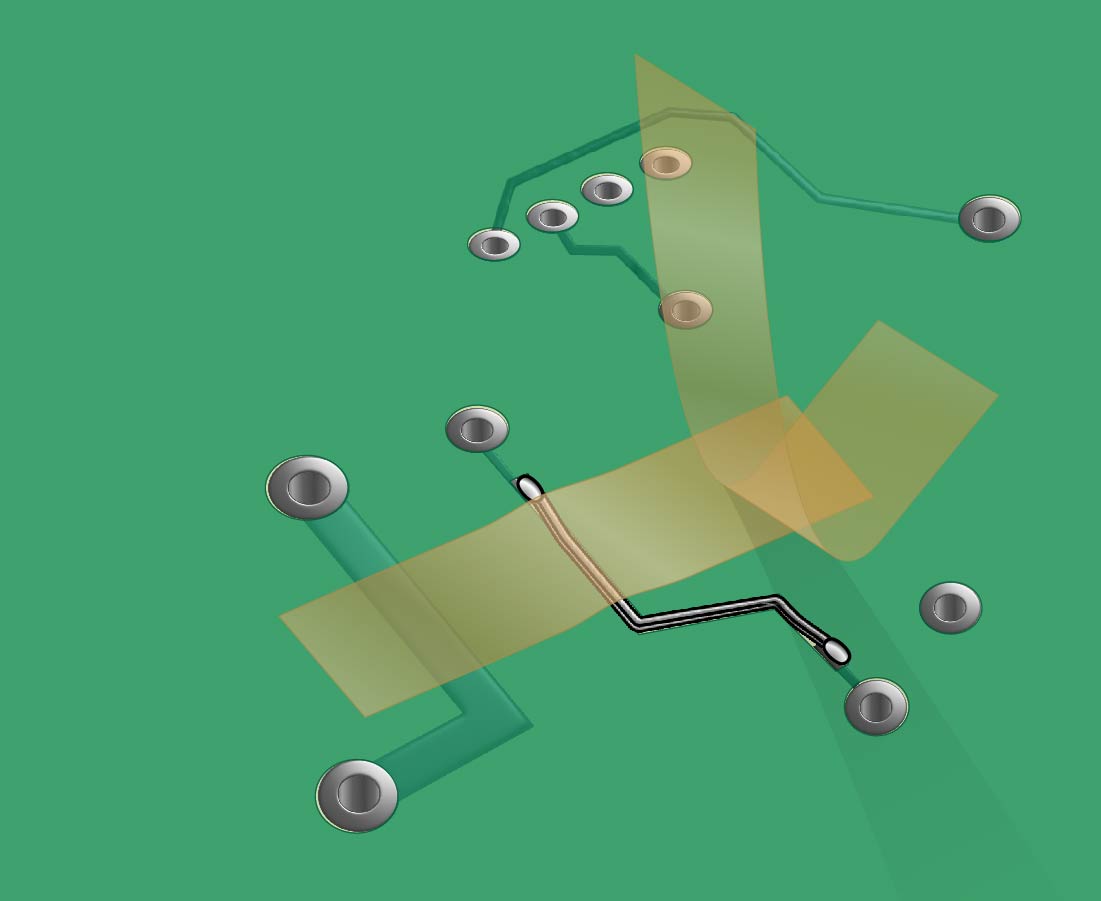

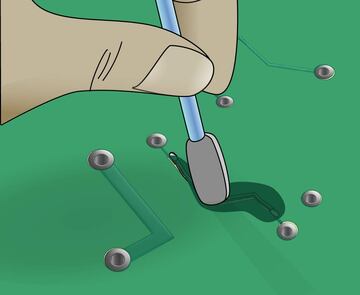

STEP 4: Solder other end of the foil jumper to contact.

|

Solder other end of jumper. |

Apply flux to the overlapped traces and solder them together. |

STEP 5: Remove tape & clean repair area.

|

Carefully remove tape.

Clean repair area. |

Clean the repair area, being careful not to move or damage the new trace. Carefully remove the tape. |

STEP 6: Apply Epoxy Overcoat.

|

Apply overcoat to repair area.

Spread and texture overcoat. |

Mix the overcoat epoxy according to the manufacturer 's instructions. Apply the epoxy over the trace with a pick. A lint free foam swab can be used as needed to thin and spread the epoxy over the sides of trace. Polyamide tape may be used to mask areas from the epoxy. Alternatively, an overcoat pen can be used to cover and protect the reapired trace as long as the coating will not be exposed to extreme soldering temeratures. The will enable a faster application and cure more quickly. Cure the epoxy or overcoat according to the manufacturer’s instructions. Do not cure at a heat which components on the board cannot tolerate, however. |

Tools & Materials

- Buffer

- Cleaner like flux remover pen or alcohol pad

- Conductor foil jumpers

- Epoxy overcoat

- Overcoat pen

- Polymide tape

- Knife

- Wire solder

- Soldering iron with tips

- Shear cutter