CircuitWorks Conductive Paint

CircuitWorks Conductive Paint makes instant highly conductive silver traces on circuit boards.

CircuitWorks Conductive Paint makes instant highly conductive (0.02-0.05 ohms/sq/mil) silver traces on circuit boards and is used in the prototype, rework, and repair of circuit boards by linking components, repairing defective traces, making smooth jumpers and patching EMI shielding. The silver traces dry in minutes and has excellent adhesion to most electronic materials. Engineers, repair technicians, and manufacturers will find that the CircuitWorks Conductive Paint speeds project completion and cuts rework time.

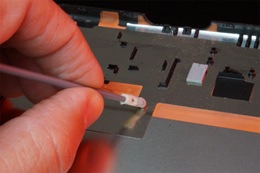

CircuitWorks Conductive Paint comes with a pick, 2 small brushes, and 2 lint-free foam swabs for easy application. The brushes and swabs are ideal for larger areas, like for shielding repair, and the pick allows for precision trace repair.

Cures tack-free in 3 to 5 minutes at room temperature. It achieves electrical conductivity within 30 minutes. Heat cure for 5 minutes at 250°-300°F (120°-150°C) for maximum conductivity, durability, and chemical resistance.

Features & Benefits

- Single component system

- High electrical conductivity

- Fast drying

- Highly adherent to circuit boards

- Operating temperature to 400°F (205°C)

APPLICATIONS

- Circuit trace repair

- Solderless linking of components

- EMI shielding

- Solderable terminations

- Quick prototype modifications

| TDS | |

| REGS | |

| SDS | |

| Categories |

| Shelf Life | 15 mo. |

|---|---|

| Specs | ANSI/IPC J STD-001, IPC-7711 |