Your Sample Request

Konform AR Acrylic Conformal Coating

*=required field

TDS

REGS

SDS

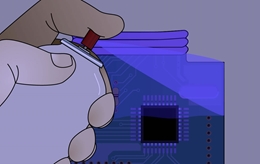

Konform AR Acrylic Conformal Coating

UL-certified acrylic conformal coating for insulation against high voltage arcing and shorts

Konform AR is ideal for providing insulation against high-voltage arcing and corona shorts. This extremely effective acrylic conformal coating provides a hard, durable protective barrier against humidity, salt, corrosive vapors and fungus for

Features & Benefits

- Acrylic coating working temperature from -75°F/-59°C to 279°F/137°C

- High dielectric strength of 8300 volts/mil

- Passes the laboratory tests of MIL-I-46058C. However, it is not qualified on QPL-46058.

- Compliant to IPC-CC-830A

- RoHS Compliant

- Provides excellent acid resistance

- Will not discolor over time under normal use

- Easily repairable

- Contains a UV indicator for thorough Quality Control inspection

- UL Recognized, File E76307

Applications

- Extends component life by protecting against adverse environments

- Resists moisture, salt, fungus, corrosive vapors, and severe environments

- Designed to provide effective insulation against electrical shorts and harsh environments

| TDS | |

| REGS | |

| SDS | |

| Categories |

| Specifications | IPC-CC-830A,UL Recognized |

|---|---|

| NSN |

CTAR-1 - 5970-01-417-4156 CTAR-12 - 5970-01-417-4158 |

| Shelf Life | 2 yrs. |

Articles

HOW-TO: Conformal Coating Application Using Aerosol Spray

Webinar: Optimizing Selective Spray Conformal Coating for Maximum Output

Conformal Coating Defects: When Things Go Horribly Wrong

The Ultimate Guide to Conformal Coating

How To Evaluate The Best Silicone Conformal Coating

8 Essential Tips for Conformal Coating Dip Application