Your Sample Request

Soder-Wick Unfluxed Desoldering Wick

*=required field

TDS

REGS

SDS

Soder-Wick Unfluxed Desoldering Wick

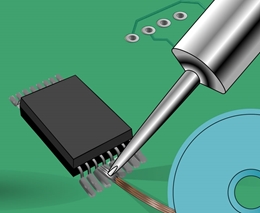

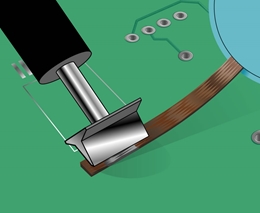

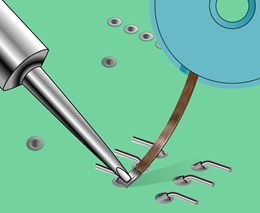

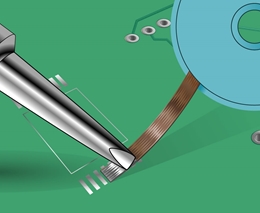

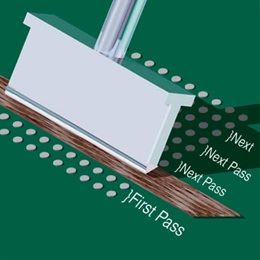

Soder-Wick brand desoldering wick offers the state of the art in desoldering technology. Soder-Wick is designed for today’s heat sensitive electronic components using lighter mass, pure copper braid construction that allows for better thermal conductivity, even at low temperatures. Soder-Wick responds faster than conventional desoldering braids thereby minimizing overheating and preventing PCB damage.

All wick is sealed in nitrogen-purged packaging to avoid corrosion and loss of performance from moisture and oxygen.

|

| 25 bobbins in resealable pouch |

Features & Benefits

- Can be coated with any flux type

- Allows for a constant flux type throughout the production process

- Provides quick and safe desoldering

- 10' spools packaged in ESD-safe static dissipative bobbins

Applications

- Use with your specified flux type throughout the production process

Specifications:

- MIL-F-14256 F

- NASA-STD-8739.3 Soldered Electrical Connections

- DOD-STD-883E, Method 2022

- ANSI/IPC J STD-004