Note: This guide is based on the IPC 7711 4.4.1 standard. Purchase the full standard from the IPC organization. The graphics and text have been created to provide easy-to-use instructions. Any content that diverges or supplements the IPC standard with be noted on the graphics, and text will be blue.

This is a process to remove solder from a row of SMT lands using a blade tip. IPC7711 number 4.1.3 describes a process to do this without a blade tip. Click here for a how-to guide of that process.

Step 1: Choose braid width and solder tip

|

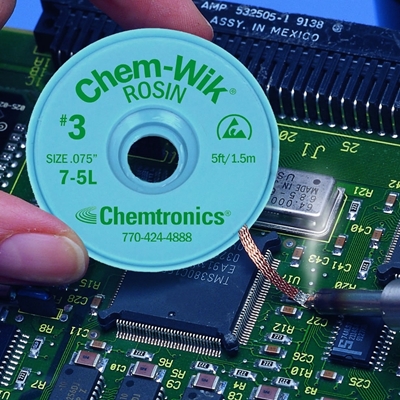

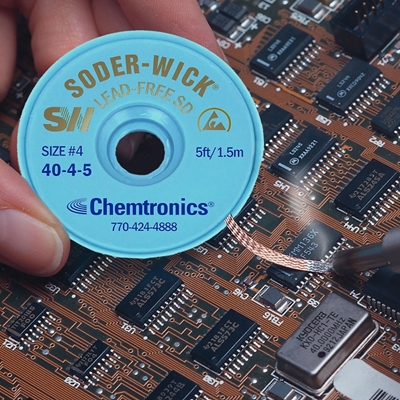

Select solder wick width.

Select solder tip size. |

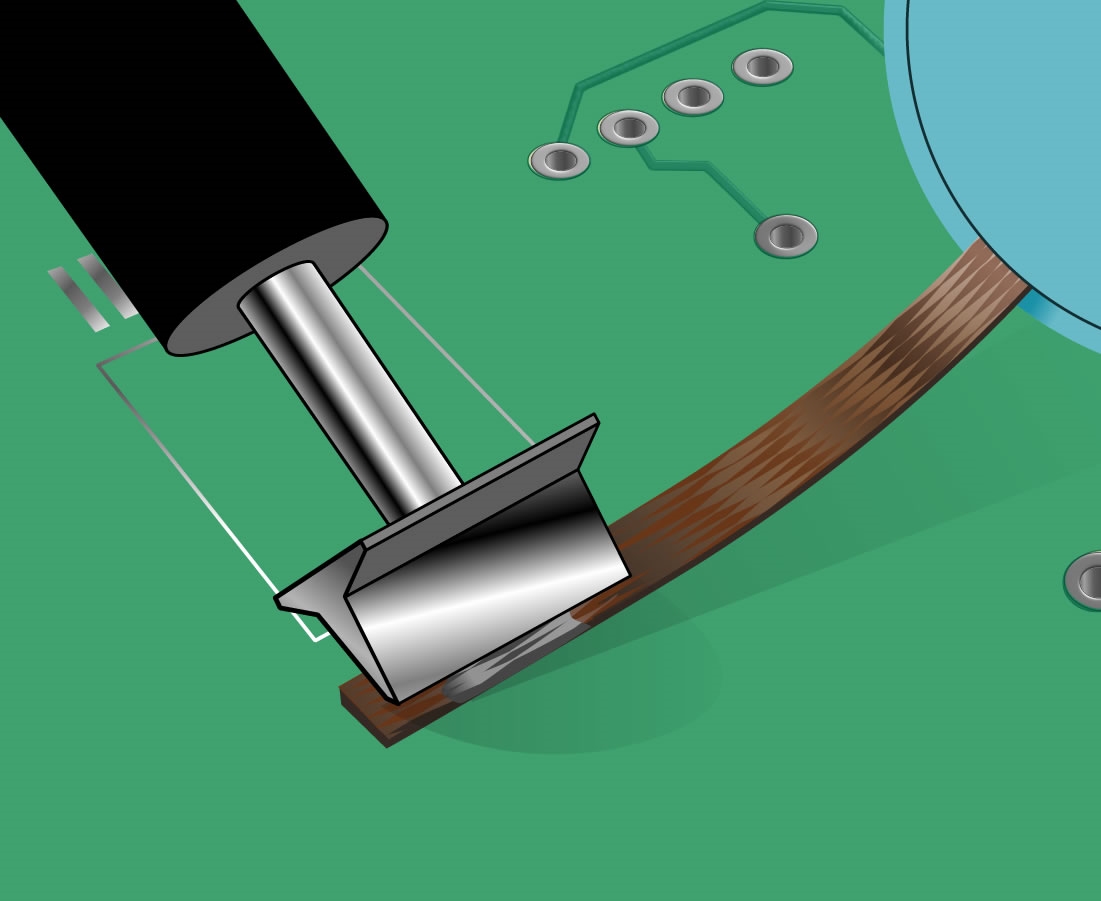

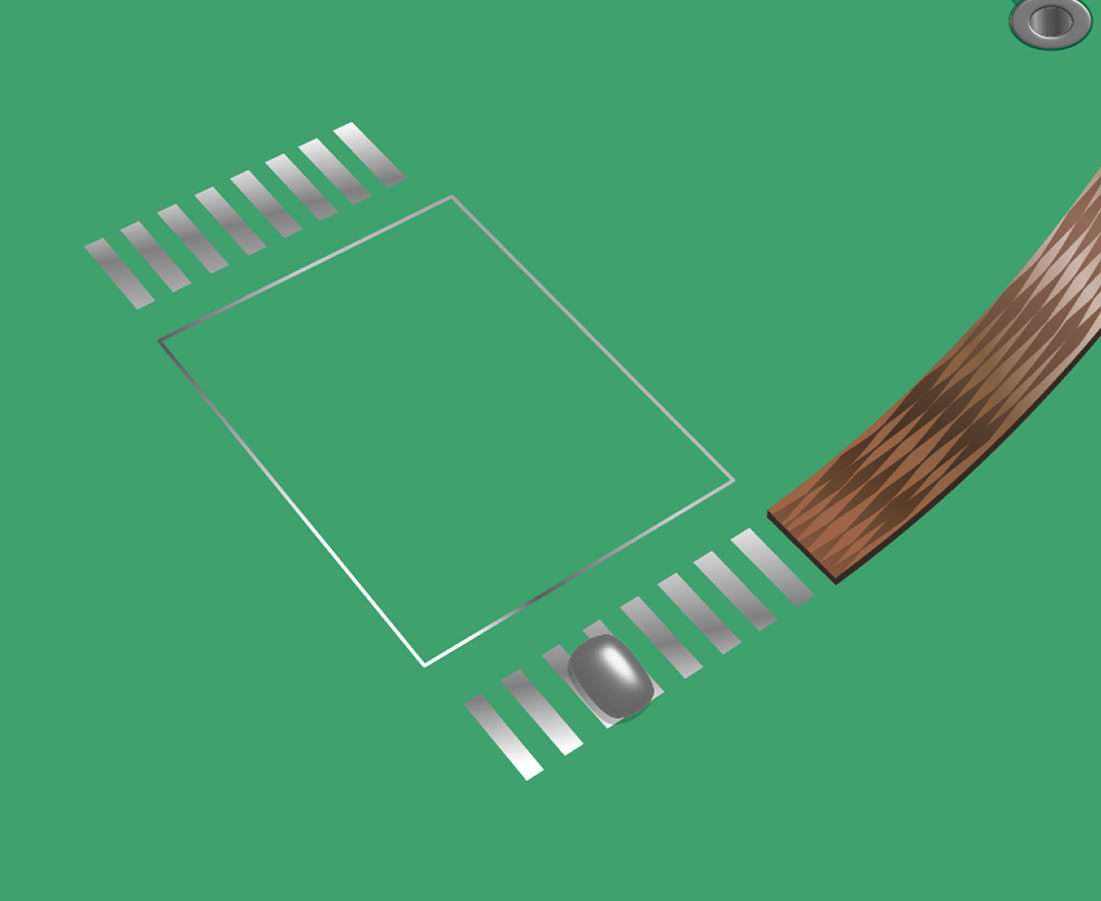

Choose a width of braid that is approximately the length of the lands from which solder will be removed. Slightly thinner braid can be used, but do not use braid that is too wide. Choose a blade solder tip that is as long across as the row of lands. Choose a desoldering braid that is coated with a flux that meets your requirements. Apply your own flux to unfluxed braid if use of a specific flux is required (not common). |

Step 2: Prepare iron

|

Clean solder tip. |

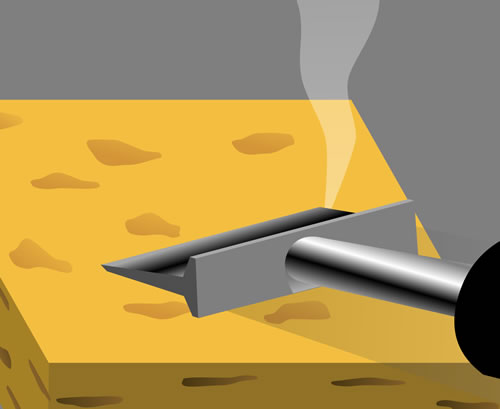

Select a temperature of approximately 315°C (599°F), and adjust as needed. Clean the solder tip. |

Step 3: Melt and Remove the solder

|

Apply flux.

Remove solder from SMT land.

Remove solder from BGA pads. |

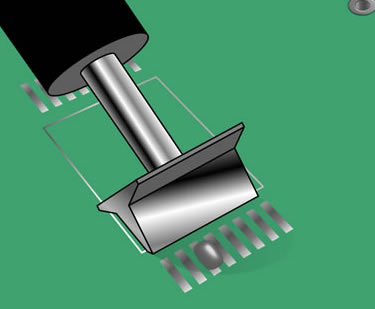

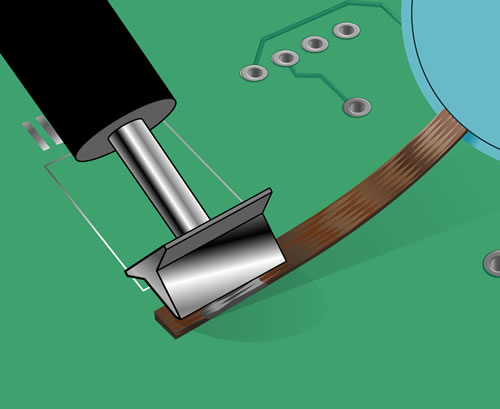

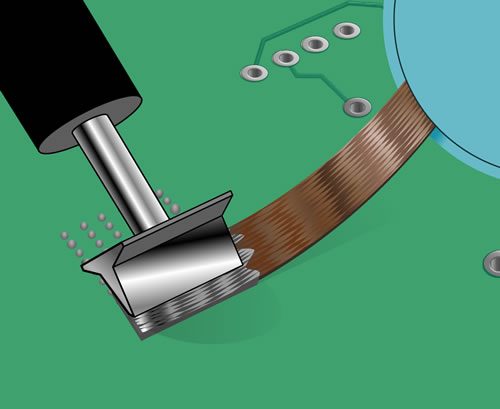

Apply flux to the lands. Lay the braid across the row of lands and then place the flat beveled surface of the iron tip on the braid directly over the solder to be removed. Allow heat to conduct through the braid to melt the solder. The braid will absorb solder using a wicking action. Use caution holding the braid, as heat will also travel through the braid. Move the braid in the direction of the length of the lands if the braid must be moved to absorb all of the solder. Dragging the braid across the row of lands while they are heated may cause a land to lift and risks scratching land surfaces. This same process can be used to remove solder from BGA pads. |

Step 4: Remove the Braid

|

Lift solder wick and tip. |

Remove soldering iron and the braid at the same time immediately when wicking action has ceased. Trim away used areas of the braid. |

Step 5: Clean.

|

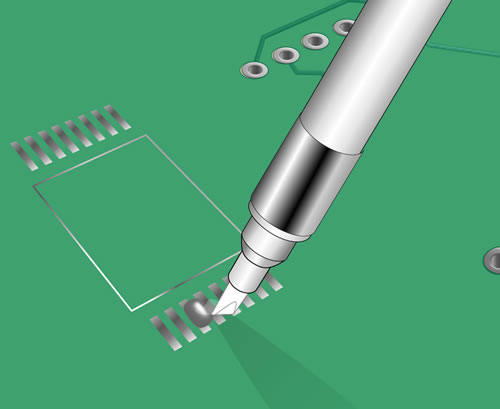

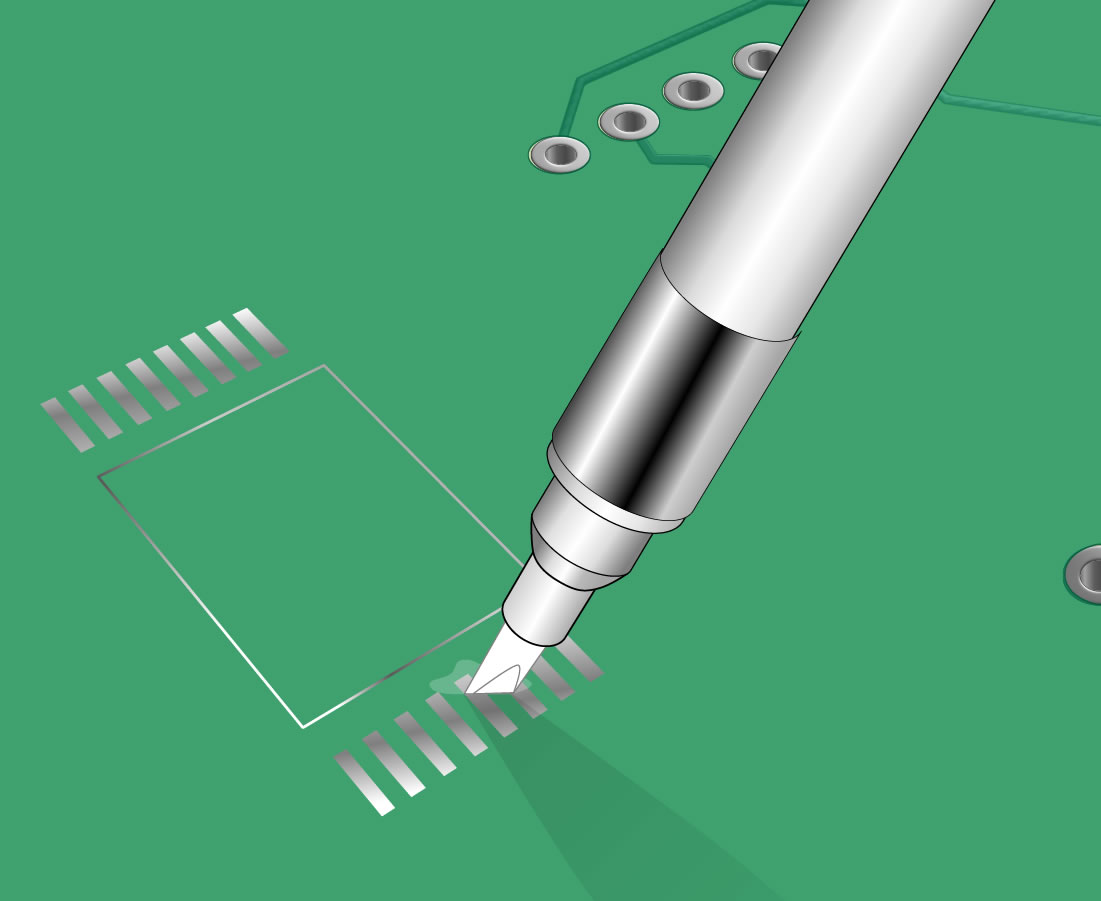

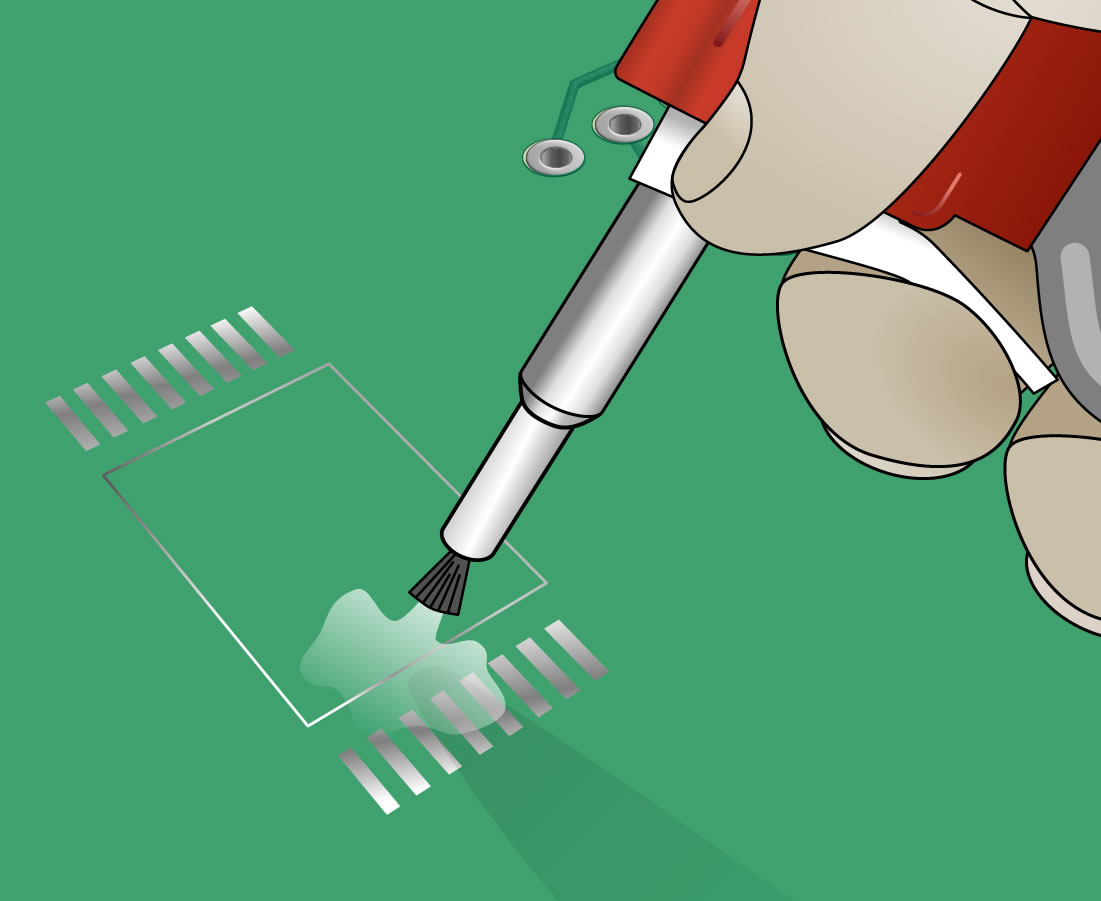

Remove flux residue with a pen...

or aerosol with a brush. |

Clean and inspect area. |

Tools & Materials

-

Cleaner like flux remover pen or aerosol flux remover

-

Soldering iron with tips

-

Solder sponge or brass tip cleaner