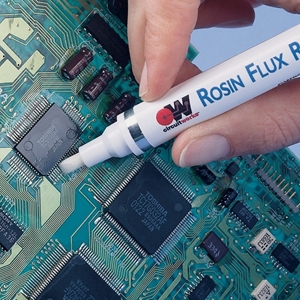

CircuitWorks Flux Remover Pens

Pen for precise removal of flux from printed circuit boards

CircuitWorks Flux Remover Pens are designed specifically to remove each type of flux:

- Rosin Flux Remover Pen quickly cleans type R, RMA, and RA flux residues.

- No Clean Flux Remover Pen precisely removes both organic and synthetic low solid no clean fluxes.

- Lead-Free Flux Remover Pen quickly cleans type R, RMA, and RA rosin flux residues as well as organic and synthetic no clean fluxes used in higher heat lead-free applications.

Features & Benefits

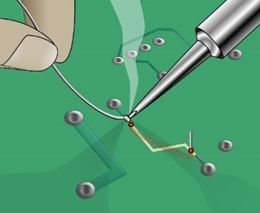

- Completely removes flux in seconds

- Spot cleans tight tolerance areas on circuit boards

- Marker dispenser provides controlled spot cleaning

- Dries fast

| TDS | |

| REGS | |

| SDS | |

| Categories |

| Shelf Life | 5 yrs. |

|---|---|

| Specs | ANSI/IPC J STD-001, IPC-7711 |