Cleanroom-grade wipes are designed to reduce the generation of particulate contamination when used in a critical environment. When choosing a wipe for critical equipment cleaning, there are several important features to consider. Here are eight of the most important features:

1. Material

The wipe material should be compatible with the cleaning agent being used and should not damage the equipment. Common wipe materials include polyester, polypropylene, and cellulose.

2. Absorbency

The wipe should have sufficient absorbency to effectively remove contaminants without leaving residue or streaks.

3. Low Linting

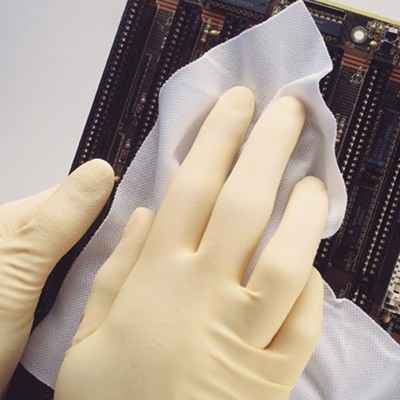

The wipe should not shed lint or fibers during use, as this can contaminate the equipment being cleaned and cause malfunctions.

4. Softness

The wipe should be soft to avoid any scratching or damage to delicate surfaces of the equipment.

5. Durability

The wipe should be strong enough to withstand vigorous cleaning without tearing or falling apart.

6. Size

The wipe should be an appropriate size for the equipment being cleaned, ensuring that it covers the entire surface area and allows for efficient cleaning.

7. Sterility

In some critical applications, the wipe may need to be sterile to prevent the introduction of bacteria or other contaminants.

8. Compliance

The wipe should comply with any relevant industry standards or regulations, such as ISO 14644 for cleanroom environments or FDA regulations for use in food processing equipment.

It is important to choose a wipe that is specifically designed for critical equipment cleaning to ensure that it meets all necessary requirements and effectively removes any contaminants without damaging the equipment.

Coventry Cleanroom Wipes

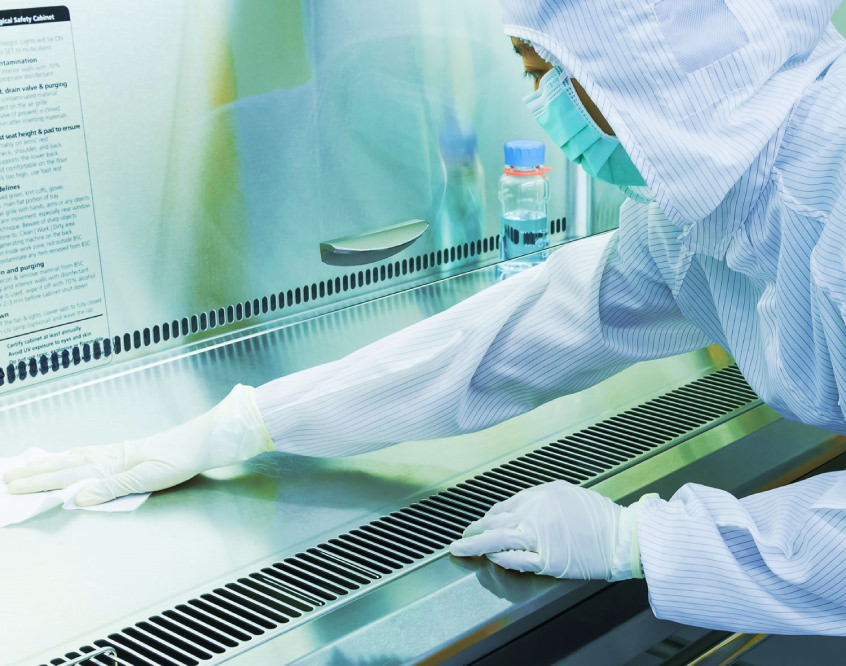

Coventry cleanroom-grade wipes are designed and processed to reduce the generation of particulate contamination when used in a critical environment. All cutting, laundering and packaging operations are designed to eliminate or greatly reduce the introduction of particulates into the product and their subsequent introduction into the critical environment.

Coventry wipes are double-bagged, so the outer bag can be removed in a staging area, and then the inner bag wiped down before being brought into the critical environment. Coventry cleanroom wipes can be used for general cleaning, but are economically best for critical environments where particulate contamination is of greatest concern.

Coventry Cleanroom Laundered Polyester Wipes offer an extra level of protection for critical applications. Our Poly-wipes are made from 100% continuous filament polyester – the standard in cleanroom wipes – minimizing particle generation. Poly-wipes are laundered in our Class 10 (ISO Class 4) cleanroom, and are available with our exclusive heat-cut edge sealing process.

Coventry Cleanroom Chamois is the only wipe made from a 50/50 nylon/polyester microfiber blend providing superior toughness and particle entrapment. The microfibers in the Cleanroom Chamois have a unique wedge shape, which lifts all types of contaminants from the surface more effectively than conventional round fibers. Cleanroom Chamois are laundered in our Class 10 (ISO Class 4) cleanroom, and are available with our exclusive laser-edge sealing process.

Poly Double-Onyx™ ESD Wipes are made from second-generation black no-run monofilament polyester knit, providing excellent strength, absorbency and chemical compatibility. These wipes are perfect for general cleanroom and equipment maintenance, or any critical applications where lint is not tolerated. The black color makes them uniquely valuable as inspection wipes for light-colored soils and dust. The conductive carbon filaments are knitted into both sides of the wipes and twice as densely packed as other ESD wipes, for maximum continuity to ground in the 107-109 range.

For a case study on how Coventry wipes were successfully introduced into a medical device manufacturing facility, check out our article “How Coventry Wipes Reduced Contamination in a Medical Device Manufacturing Process by 90%”.

For more information, contact your Coventry cleanroom application specialist at 678-928-6534 or [email protected].