Customers can optimize their processes utilizing Chemtronics’ expertise and facility which offers state-of-the-art cleaning, coating and analytical services. Using batch, ultrasonic and vapor-degreasing systems, Chemtronics can duplicate your production environment for process optimization and troubleshooting, while ensuring compliance, safety and affordability. We can clean products, identify a problematic process or product, or can identify a product to assist your normal processes.

Analytical Equipment

The Chemtronics Analytical Facility analyzes incoming raw materials, outgoing finished materials or troubleshoots any kind of chemical problem our customers might be having. The equipment is used for internal qualifying, product development, quality control, but is also available for our customers needing the same services.

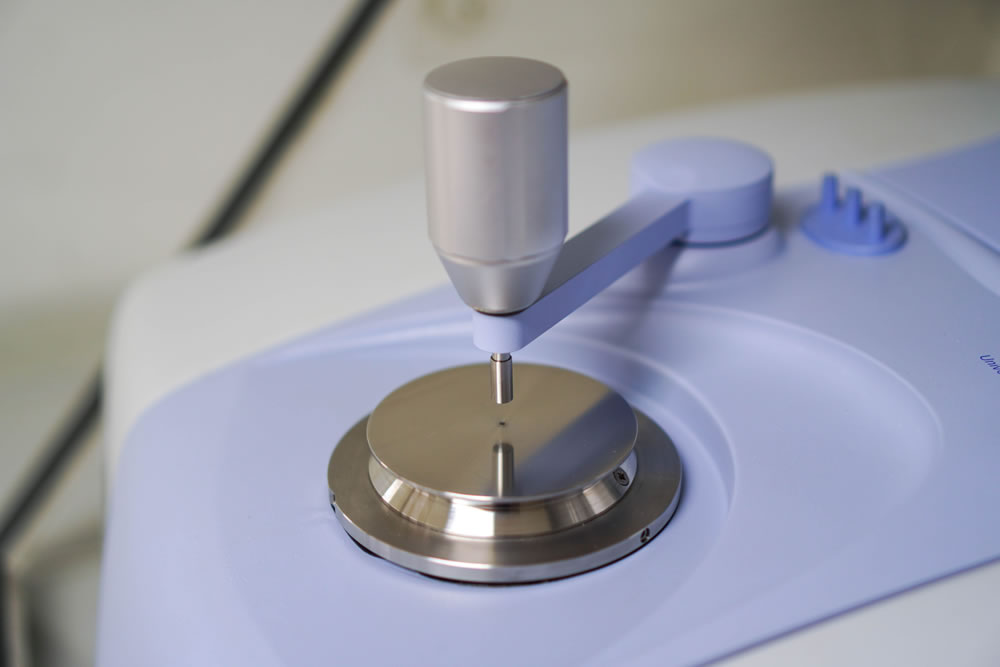

Figure 1: FTIR (Fourier-transform infrared spectroscopy)

Our FTIR (Fourier-transform infrared spectroscopy) can provide a detailed fingerprint of a chemical or a chemical blend.

The Gas Chromatographer (GC) can separate out components of volatile solvent mixes to identify the exact chemical composition and quantity of each. This process qualifies internal products, but it can also identify unknown fluids or the molecular level components. Knowing what the molecule is and the atoms in it informs us about what the product does, how it’s supposed to accomplish it, and whether it is working properly.

Figure 2: Gas Chromatography Unit.

The GC and FTIR are critical devices to help determine if there is a contaminant in a product. Identifying the specific molecular composition of the material can reveal if there is a contaminant and at what level. For example, the FTIR can determine if silicone is a contaminant, as silicone absorbs IR at a specific wavelength.

Chemtronics makes coatings as well as volatile chemicals. The lab ensures viscosity is properly calibrated in our coating formulations.

In addition, Chemtronics has the basic instruments for product assurance or to test customer specimens. Flow cups, densitometer, and PH meters are essential complements. Moisture is a critical quality control feature in solvents, for which we use Karl Fischer Titrators to measure moisture content. That can be a critical test for any problematic solvent a customer may be encountering.

Contamination and Cleaning

The Chemtronics Analytical room is often just the first step for many customer products. Contamination is a common issue for many. They need help to identify it, in order to prevent recurrence, but they also often need it to be removed or advised how best to remove it.

Chemtronics lays out the ideal contamination removal procedure for the processes each customer may have.

For most soiled parts that come into Chemtronics, vapor degreasing is the first, and often is the only necessary, step. The advanced degreasing process safely optimizes the cleansing process regardless of the cleaning time or solvents required. But for more mysterious contaminations, we analyze it first.

Additionally, customers request we qualify which solvent is appropriate to their parts, manufacturing process, and potential contamination.

The first step is to identify the contamination and the substrate. It’s imperative we remove the contamination yet not adversely affect the parts or components.

Vapor Degreaser

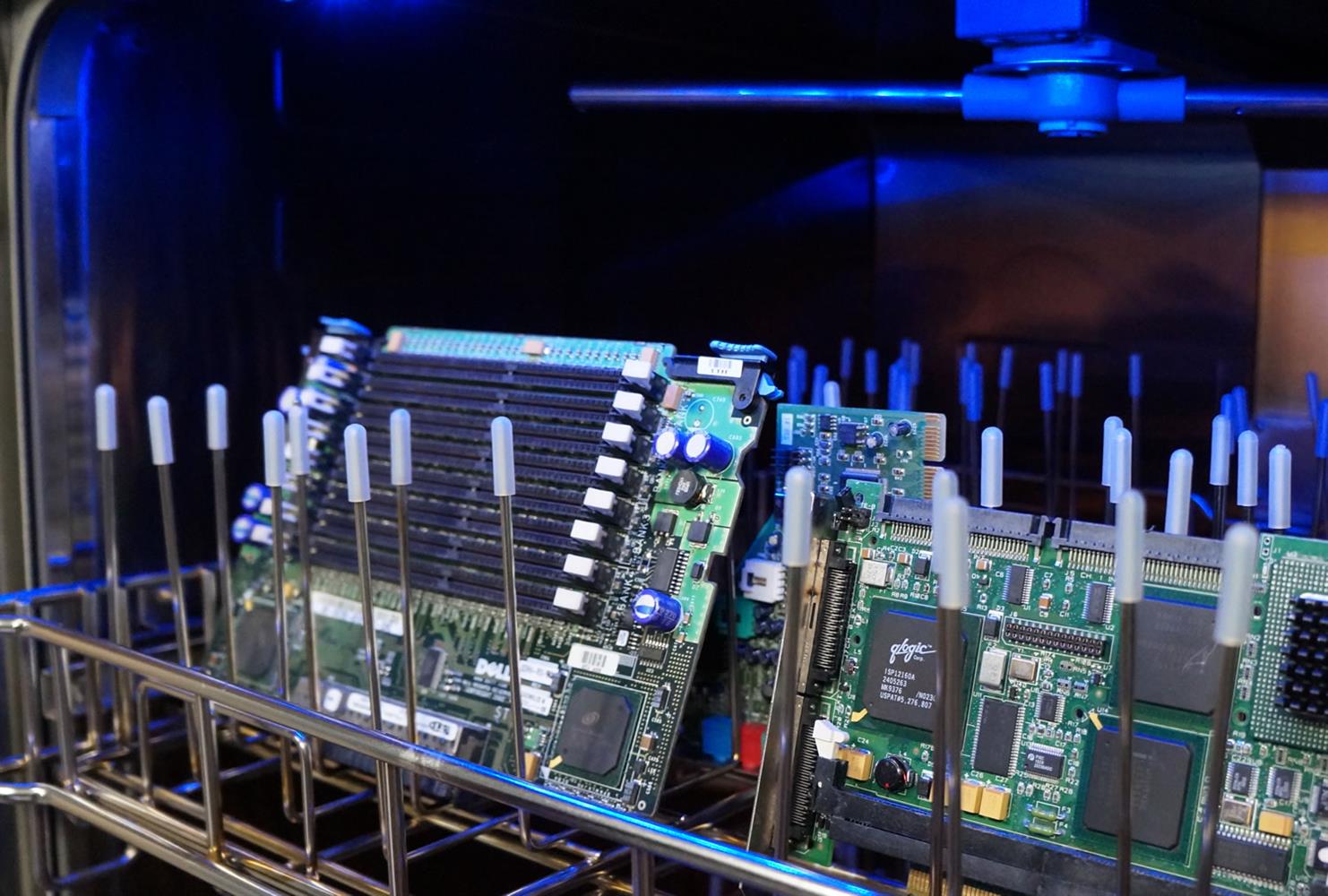

Chemtronics vapor degreaser can closely simulate a customer’s cleaning process. In this way, we can determine the cleaning sequence and intervals for it to be efficient, effective and safe when removing contamination in the customers facility.

Vapor degreasers are a perfect solution to clean parts because you are always washing with pristine, clean solvent as it self-distills and self-purifies as part of the process.

The protocol entails cooling the part by first putting it in the cold sump which is equipped with an ultrasonic. This cools the part and also mechanically removes contamination. The cold part is then put in the vapor zone. The vapor will condense on the part resulting in a pristine part.

If there is stubborn contamination, the part is run through multiple cycles, submerged in a sump with ultrasonics, or subjected to a spray wand. Some soils may require mechanical cleaning in addition to the vapor degreasing.

Click here for more information on vapor degreasing.

Figure 3: Vapor Degreasing Unit.

Water-based Cleaning

Chemtronics uses water-based cleaning where feasible to be environmentally conscious. Our batch cleaner scales up in small quantities. We can work with one or two gallons with parts customers send in, then check the cleanliness and performance.

We manufacture parts, which helps to test cleaning processes on new substrate materials to match precise customer specifications. We can do printed circuit boards with surface mounts and through holes. Once we make the test boards with the various fluxes we want to test, we bring it to our batch cleaner and run through our cycles with either neutral or alkaline cleaners.

After those test cycles, we take them to inline cleaning stations and scale up to a long run of boards with 10 or 20 gallons of solvent. There we test the aging and the full process.

Figure 4: Aqueous Batch Cleaner.

Other Cleaning Processes

Chemtronics adapts to the component, customer needs as well as the specific contamination as another method may be preferred or even required. We check discrete areas of the soiled part with brushes, swabs, or with wipes to identify the best process for our customers. The cleaning process chemistry may not quite fit with the goals of the customer. We simulate the best process among all our services for the customers to find the best, most efficient process for them.

Click here for best practices for manual cleaning electronics.

Conformal Coatings

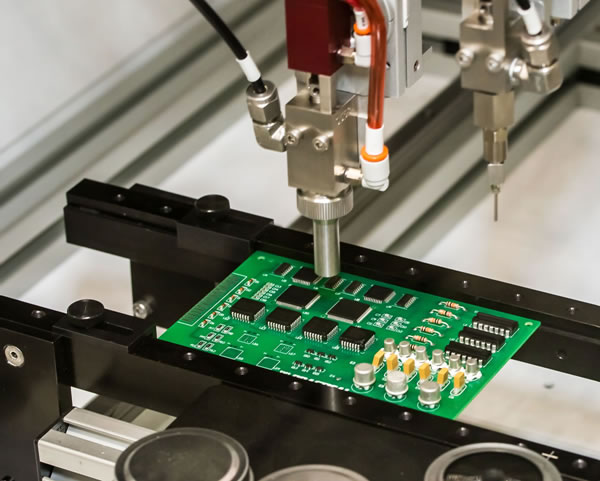

We want to make sure that our conformal coatings are tested, applied, and developed on actual machines that the customers will use. Chemtronics has a lab-size PVA machine to test all our new conformal coatings, whether that is a silicone, urethane or acrylic-based, to make sure it operates as designed on the line. We also use the PVA to do larger series of panels for statistical or UL testing as well.

Figure 5: Conformal coating selective spray system

As the main purpose of conformal coating is to prevent grounding by insulating the board, we want to make sure that the board or the coating will insulate up to specifications. For example, a panel from UL 746E testing is coated to the specified depth, connected via leads to the machine, and then tested at incremental increases to find susceptible levels. Testing begins at 1,000 volts, and if 6,500 volts is achieved without a spark or breakthrough then it’s a good product.

Manufacture Test Boards

Focused on customer satisfaction and trust, Chemtronics tests substrates that customers will be using, which means we need to test our products on printed circuit boards similar to customers’ specifications. To achieve that, we manufacture our own printed circuit boards simply to test our products.

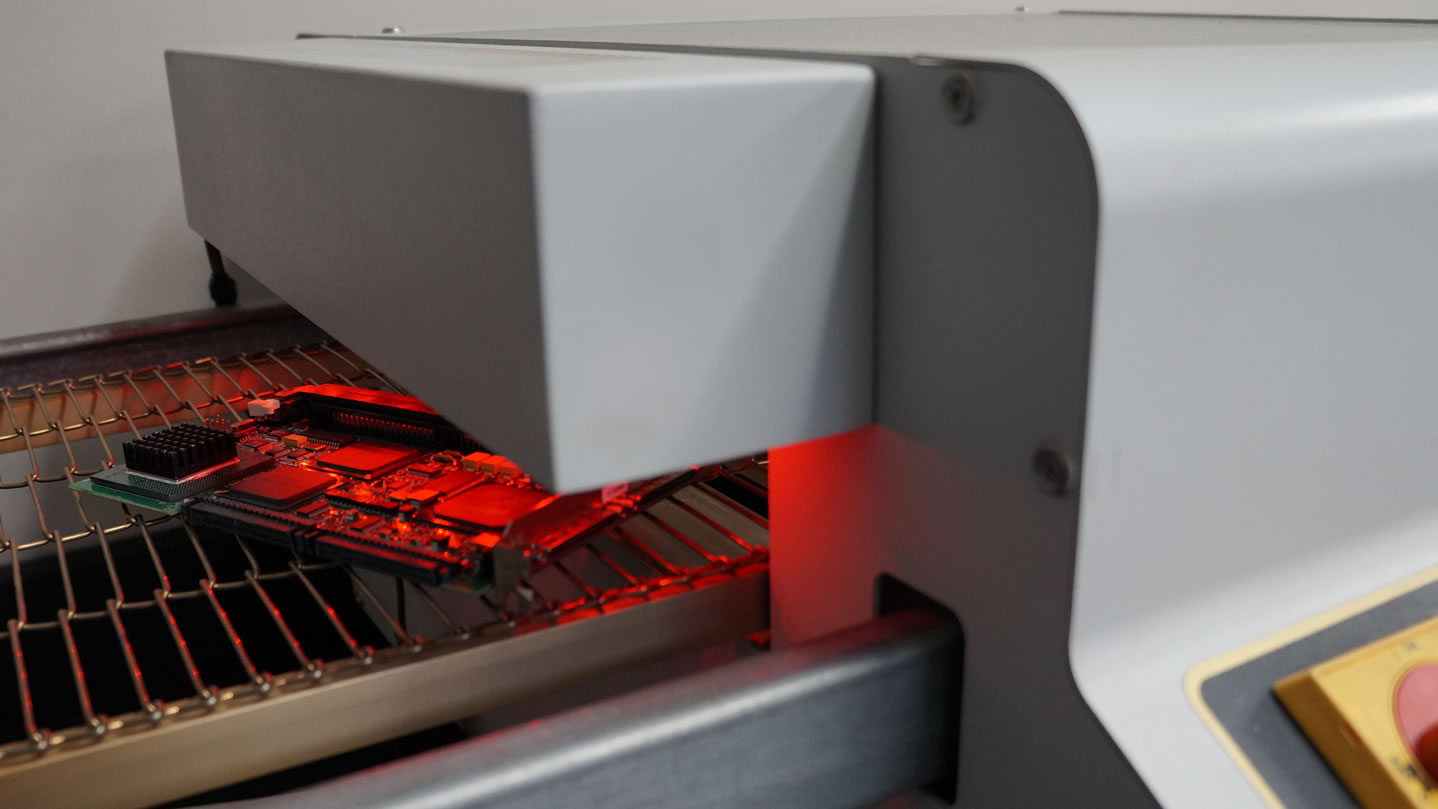

A lab-size reflow oven applies surface mount components onto test boards. We have particular boards and dummy components, and depending on our clients’ needs, a range of fluxes and solder pastes. We create the board with a variety of flux or solder pastes, then in the cleaning steps we identify which of those fluxes or pastes a given solvent can efficiently remove.

Figure 6: Reflow oven to manufacture boards for testing.

If a customer is considering changing a process to include a new solder paste, then we apply that paste on test boards per their proposed process, then test them. Since we manufacture our own dummy boards, we can destructively test to identify critical flaws, particularly what may be stuck beneath surface mount devices.

Free Chemtronics Qualification Testing

Contact Chemtronics for free qualification testing. We are available to help qualify new cleaning processes, evaluate current processes, or troubleshoot contamination issues. We can test actual production samples or use our specially designed cleanliness testing board.

Chemtronics develops new products for our own use, and to service and demonstrate our various products for both manufacture or cleaning, and to help you, our customers, optimize your processes for the changing technology landscape.

Let’s work together to optimize your cleaning & coating processes. For more information, contact your Chemtronics application specialist at 678-928-6534 or [email protected].