Rear windshield defogger repairs usually involve two basic types of failures: a.) Repairing broken grid wire traces and/or b.) Re-soldering the power connection tabs. Re-soldering these connections in a repair center or work shop is virtually impossible, as access to the broken grid or connection tab is limited, metal soldering is a complex process that often needs to be performed “upside-down”, and more damage is likely to be introduced to the grid due to excessive heat use. Rather than soldering these connections, such repairs can be performed much faster, more effectively and less expensively using silver-filled conductive epoxy adhesives. Conductive adhesives create a stronger bond, which is less likely to break due to vibration, and can be more conductive than the original solder joint

How To Repair The Window Defogger Grid

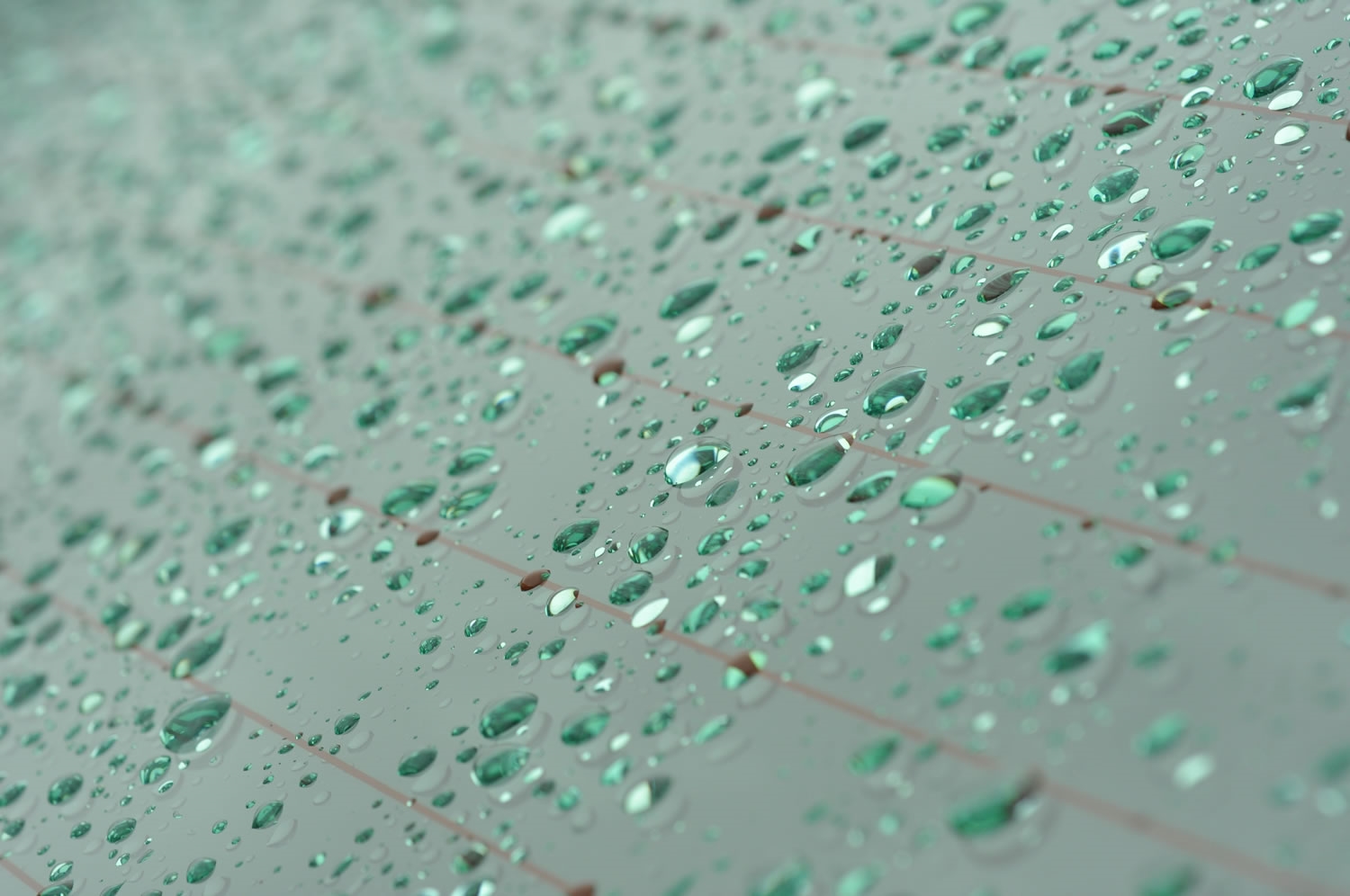

Use the CircuitWorks® Conductive Pen (Part Number CW2200STP) to repair a broken heater grid wire. First, clean the glass surface with Electro-Wash® PX Cleaner Degreaser, to effectively remove any oily films, grease or handling soils, which will interfere with the bonding of the conductive polymer to the glass. Press the pen tip firmly against the cleaned glass surface, which starts the flow of the CircuitWorks conductive ink. Start at one end of the break and draw a straight line of conductive polymer to connect to the other end of the break. Use a straight edge or masking tape to guide the pen barrel when drawing the connecting silver conductive trace. The conductive trace will dry within 5 minutes at 75°F, 10 minutes at 65°F, and 15 minutes at 55°F. Do not attempt the repair if the temperature is below 50F. Once the conductive trace is dry, test the repair for electrical conductivity. Fog and ice may not disappear at the point of the repair, but the remainder of the grid line will work properly.

How To Repair The Window Defogger Connection Tab

Power is delivered to the defogger grid through metal connector tabs, which attach to the wider, vertical grid lines that run along each side of the defogger grid. If the defogger grid does not work, one or both of these tabs could have separated from the vertical grid lines. This is readily apparent if you see dangling wires along the sides of the defogger grid. Remove the metal tab from the power plug and clean the contact surface with Electro-Wash PX or a Chempad™ pre-saturated wipe.

Use the CircuitWorks Conductive Epoxy (Part #CW2400) to reattach the connection tab to the grid. Mix at least 2 grams (approximately one-third of a syringe) of Part A Adhesive and Part B Hardener in a small container for at least two minutes, keeping the mixture as compact as possible. Once mixed, the pot-life of this material is about ten minutes, so have all work pieces cleaned and ready for repair beforehand. Clean the contact area of the vertical grid line with a Chempad pre-saturated wipe, to remove any oily film, grease or handling soils, and let it dry completely. Apply the CircuitWorks Conductive Epoxy to the contact area of the connector tab, in a thin layer. Press the tab against the contact area of the vertical grid line and secure it in place using masking tape. Wipe off any excess epoxy. CircuitWorks Conductive Epoxy will set up within four hours at 75°F or higher. If the temperature is below 75°F the epoxy may not cure properly. If this is the case heat the piece up with a heat lamp or hot air gun to maintain 75°F. Full electrical conductivity will develop within the bond in 24 hours. Test the bond for electrical conductivity.

For more information, contact your Chemtronics application specialist at 678-928-6534 or [email protected].

Ask A Technical Question

Stay up-to-date on Chemtronics news, products, videos & more.