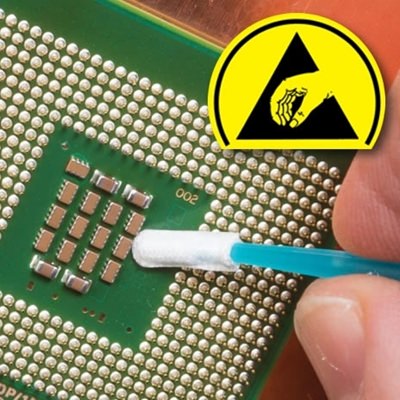

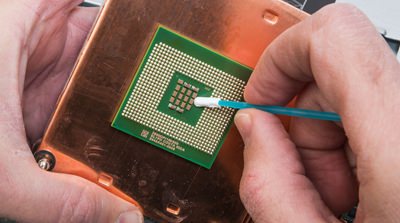

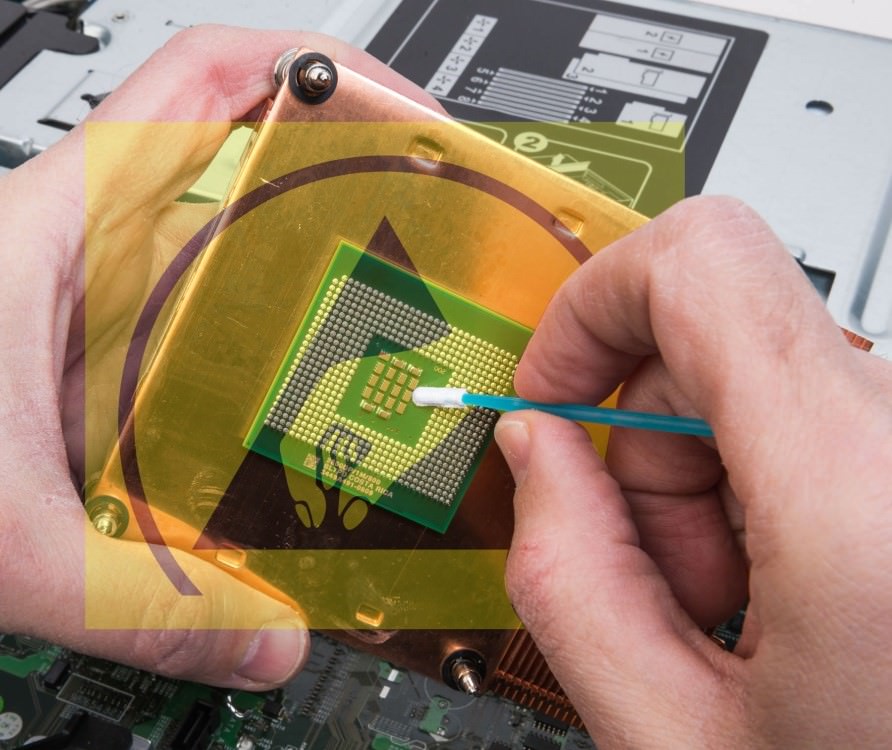

Swabs are useful precision tools for technicians and operators to perform delicate and meticulous tasks like precision cleaning, repair, and assembly. The types of swabs can range from low-cost cotton buds on a wooden stick to highly engineered cleanroom woven materials with a specialized head shape. However, there is an often unspoken risk with swabs being used on sensitive electronic circuit board… electrostatic discharge (ESD).

What Is Electrostatic Discharge (ESD)?

As defined by the EOS/ESD Association, ESD is “the rapid, spontaneous transfer of electrostatic charge induced by a high electrostatic field… Usually, the charge flows through a spark between two bodies at different electrostatic potentials as they approach one another.” (source:esda.org )

Electrons are constantly being exchanged as objects interact with each other. Problems occur when the materials involved don’t allow the electrons to flow easily and reach an equilibrium. Called insulators, they tend to collect electrons which create negatively charged hot-spots on their surface.

When these charged hot-spots come in close proximity (not even direct contact) with another object, a sudden exchange or “discharge” can occur where electrons are suddenly exchanged to create equilibrium. That event is called “electrostatic discharge”, or “ESD”.

Electrostatic discharge happens all the time, especially in dry climates and in the winter season when there isn’t moisture in the air to help bleed the excess electrons (water is conductive allowing electrons to flow more easily). Normally it is nothing more than an irritation, but with sensitive electronics it can lead to PCB failures.

When handling insulative materials like typical polypropylene swab handles a worker can generate thousands of volts. SMOS logic devices can be damaged with 250-3000 volts, EPROM devices down to 100 volts, and microprocessor chips as low as 10 volts. Damage can shut down functions or create intermittent problems, and it can either be catastrophic (immediate) or latent (later as in “field failure”). (source: Phil Storrs PC Hardware Book)

How Do Standard Swabs Create Electrostatic Discharge (ESD)?

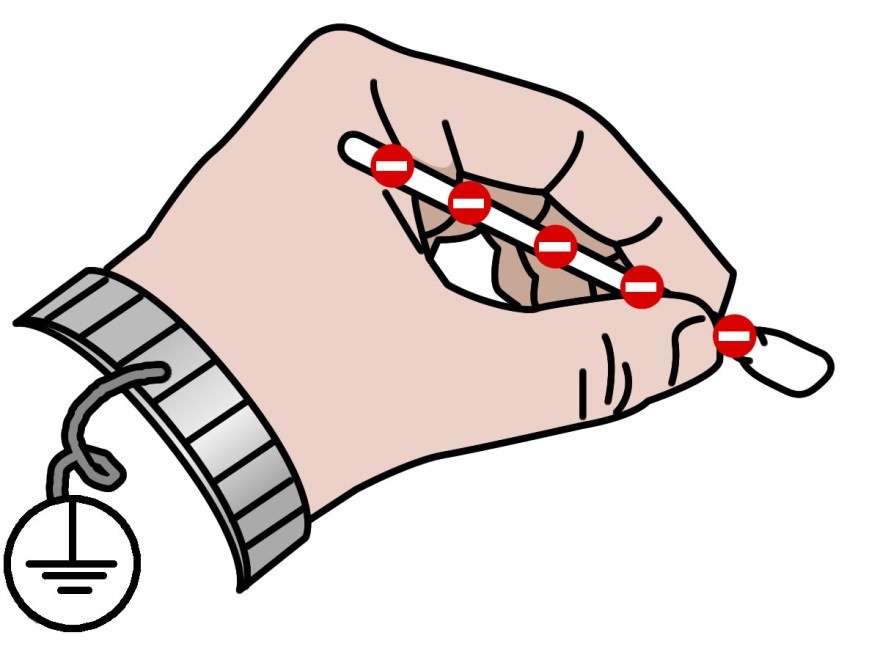

When the swab head is saturated with a solvent it can avoid static generation since the liquid is often conductive. Swab handles, on the other hand, are often made of synthetic materials and have a tendency to generate and retain a static charge. Swab handles are commonly made of polypropylene or nylon, both of which are insulative.

As the fingers and hand interact with the swab handle the friction generates a static charge. Those excess electrons collect on the handle material, and do not readily flow to ground even if the operator is using a wrist strap.

If natural materials are used for the swab’s construction, like wood handles and cotton bud swab heads, static build-up isn’t as much of an issue. These materials are generally considered “static neutral”, because they readily retain ambient moisture from the air which helps avoid static generation and discharge.

Coventry™ ESD Control Swabs

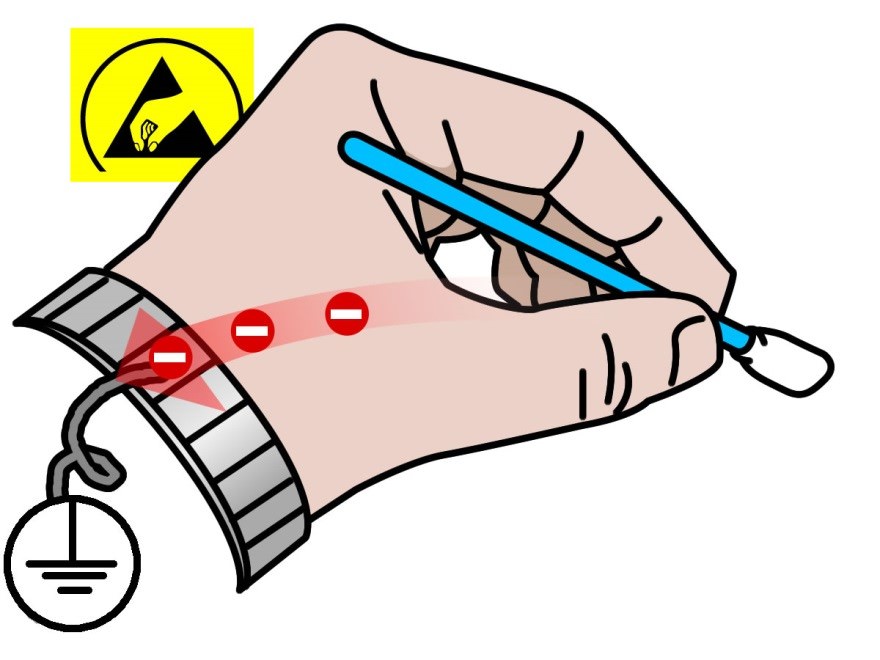

ESD-safe swabs are available from Coventry™, the premium cleanroom brand of Chemtronics®. The swab handles are made of a proprietary static dissipative material that allows the excess electrons to flow. So if the operator is grounded with a wrist strap, hot spots and electrostatic discharge will be avoided.

- Static Dissipative (Coventry ESD Control Swabs) – Surface resistivity at least 1 x 105 ohms/sq but less than 1 x 1012. Electrons flow readily to avoid both a sudden discharge and charged hot-spots.

- Insulative (standard swab handles) – Surface resistivity at least 1 x 1012 ohms/sq. Electrons do not flow readily so can create charged hot spots on the swab handles.

Examples of different types of swabs:

|

Large Foam Swab This is a workhorse swab than can be used to clean larger areas, or to apply a coating, adhesive or grease. It is made from very absorbent 100ppi (pores per inch) polyurethane foam. (Coventry part #4925ESD) |

|

Pointed Foam Swab Swabs come in different shapes and sizes to work for the application requirements. A pointed swab is able to get into tight areas and corners. (#44070ESD) |

|

Wrapped Foam Swab The seam on a typical foam swab can cause “blind spots”, areas where the foam is not as absorbent and more rigid. Normally that is not a problem but when cleaning or applying material in a tight hole, you may need a 360° usable area around the swab head. The wrapped design provides this option. (#21050ESD) |

|

Sealed Polyester Swab In applications where particulates need to be kept to a minimum, or the swab head will be exposed to aggressive solvents that might attack polyurethane foam, knit polyester swabs are available. (#36060ESD) |

|

Sealed Polyester Pillow-Tip Swab This is a version of a wrapped swab that is shaped for larger surfaces. This may be used to polish optical mirrors, for example. You have the advantages of polyester, and the seamless design is better for delicate surfaces where a typical swab’s seal areas could scratch. (#51121ESD) |

With a total of 12 varieties of ESD Control Swabs, the Coventry swab line gives you the option to switch out all the swabs currently being used around sensitive electronics in your facility. While these swabs are generally more expensive, the cost pales in comparison to the cost of PCB reliability issues for you for rework, product returns, and loss of customer goodwill.

A sample pack containing one of each Coventry ESD Control Swab is available at no charge. For more information, go to www.coventrycleanroom.com or contact us at 770-424-4888 and [email protected]